Glass & sapphire glass CNC laser cutting exhibits several properties that make it a preferred method for cutting glass materials. Here are some key properties associated with glass CNC laser cutting:

Precision

CNC laser cutting provides exceptional precision and accuracy, allowing for intricate and detailed cuts on glass surfaces. The focused laser beam can achieve precise cuts with minimal heat-affected zones, resulting in clean edges and minimal distortion.

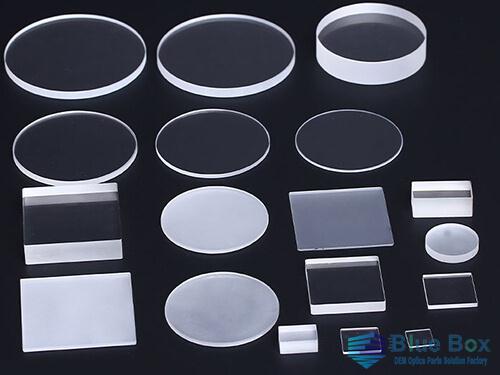

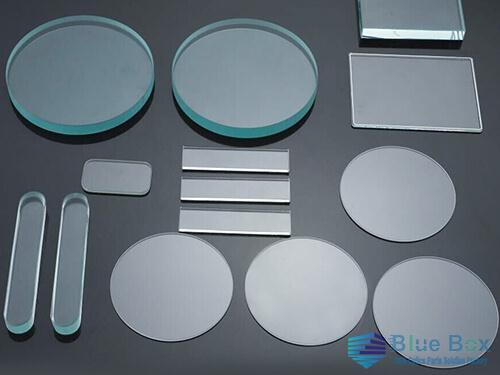

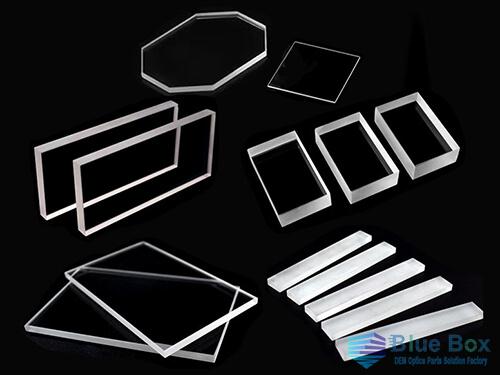

Versatility

Glass CNC laser cutting is versatile and can be used with various types of glass, including float glass, tempered glass, laminated glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Flexibility

CNC programming enables flexibility in design and cutting patterns. Changes to the design can be made easily in the CAD software, and the CNC machine can quickly adapt to the new instructions without requiring physical tool changes. This flexibility allows for customization and quick prototyping.

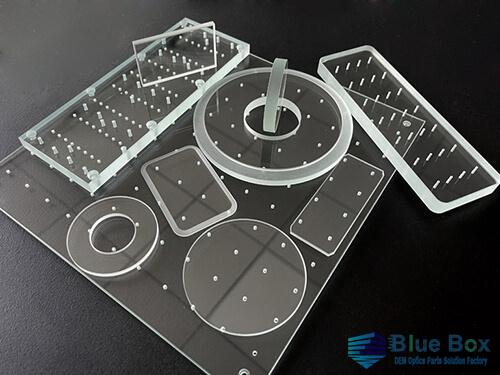

Complex Shapes and Intricate Designs

Glass CNC laser cutting can create complex shapes and intricate designs that may be challenging to achieve with traditional cutting methods. The precise control provided by CNC technology allows for the realization of intricate patterns, curves, angles, and internal cutouts.

Speed and Efficiency

CNC laser cutting is a fast and efficient process. Once the design is programmed, the CNC machine can execute the cutting process quickly and consistently, ensuring high productivity. Additionally, the automation of the process eliminates the need for manual intervention, reducing labor requirements and increasing overall efficiency.

Non-contact Process

CNC laser cutting is a non-contact cutting process, meaning the laser beam does not physically touch the glass surface. This eliminates the risk of damage or scratches caused by contact-based cutting methods.

It’s important to note that the properties of glass CNC laser cutting can vary depending on the specific laser cutting system, the type and thickness of the glass material, and other factors. It’s always recommended to consult with Blue Box optics to understand the specific capabilities and limitations of their equipment and processes.

Inquire Us