As an OEM custom laser-cutting glass manufacturer with 12+ experience, we offer our clients a wide range of services. We specialize in creating custom size and shaped glass products to meet our customers’ specific needs and requirements.

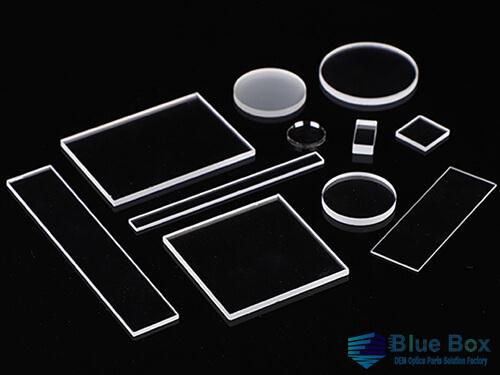

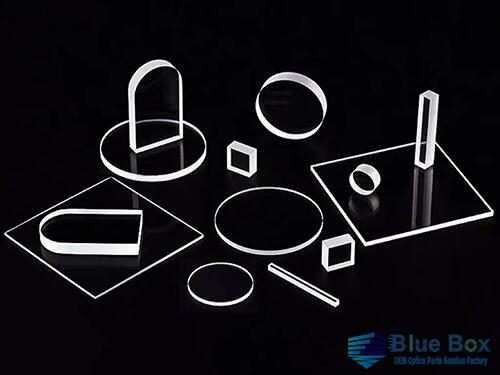

Our advanced laser-cutting technology allows us to produce precise and intricate cuts with high accuracy and efficiency. We can work with various glass materials, including clear glass, soda lime glass, borosilicate glass, quartz (Fused Silica), frosted glass, tempered glass, anti-fingerprint glass, clear float glass (soda lime), low iron glass (soda lime), and anti-reflection (AR) glass, to create a wide range of products. From glass lens replacement, watch glass, glass lens, glass disc, flashlight lens cover, tempered glass panel, sight glass window, round sight glass, touch glass, switch screen protector, switch OLED, flashlight lens, tempered glass lens, screen protector, smart light switch, and custom tempered glass lenses, frosted glass lens to custom products.

In addition to laser cutting, we offer a range of value-added services, including polishing, edging, frosted, drilling, beveling, fillet, chamfer, tempering, and so on to help create the perfect finished product for our clients.

Our team of experienced professionals is dedicated to providing the highest quality products and exceptional customer service. We take pride in delivering top-notch products that meet the needs of our customers and exceed their expectations.

If you have a project in mind and are in need of an OEM custom glass cut service, we would love to help bring your vision to life. Please do not hesitate to contact us with any questions or to discuss your project in more detail.

We support free sample service to save your cost.

Inquire Us