Sapphire substrate refers to a thin slice or wafer made from sapphire material. Sapphire substrates are commonly used as a base or foundation for various electronic, optical, and semiconductor applications.

Sapphire, a crystalline form of aluminum oxide (Al2O3), possesses excellent optical and mechanical properties, including high transparency across a broad range of wavelengths (from ultraviolet to infrared), high thermal conductivity, extreme hardness, and resistance to scratching and chemical corrosion. These properties make sapphire substrates ideal for numerous applications where durability, optical clarity, and thermal stability are essential.

In electronics, sapphire substrates are frequently used in the production of light-emitting diodes (LEDs), radio frequency (RF) integrated circuits, and high-power electronic devices. In optics, sapphire substrates serve as a foundation for optical components such as lenses, windows, and mirrors, particularly in harsh environments where traditional optical materials might degrade.

In semiconductor manufacturing, sapphire substrates are used as a substrate for epitaxial growth of semiconductor materials, such as gallium nitride (GaN), for applications like high-power electronics and optoelectronic devices. Sapphire’s high thermal conductivity and compatibility with GaN make it an excellent choice for such applications.

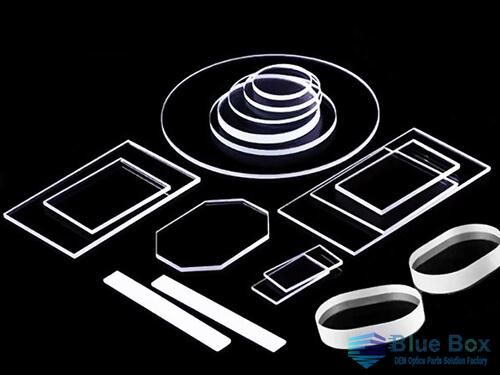

Blue Box optics provides custom sapphire substrate service, from thickness to shape. Contact us to get a free quote for your custom sapphire substrate parts.

Inquire Us